Key Advantages

- Pro/Engineer

- SolidWorks

- CATIA

- Unigraphics

- Mastercam

- ANSYS Mechanical FEA

- MoldFlow

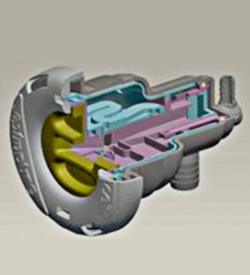

dlhBOWLES integrates computer aided design to ensure consistency throughout all stages of a part's life, with R&D, engineering, tooling, process and manufacturing functions all under one roof. We practice concurrent engineering and design for manufacturing and assembly for robust product designs.

We are committed to our customer from beginning to end. We offer strong engineering support at component-, subsystem- and system-level design, leveraging our expertise in fluid flow and related technologies.

Our expert designers are skilled in advanced surfacing and reverse engineering projects, as well as product functional and aesthetic design. We arrange Pro/E training from a PTC certified instructor for our engineers, and we frequently hold informal user group meetings and seminars.

Quality and innovation are designed in by many companies, but support is a regularly overlooked attribute in a flawless launch or during the ongoing success of a product. dlhBOWLES Fluidics considers our customer support second to none—and our customers agree. We assure predictable and successful launches by being the singular source to design and coordinate the supply of pressurized washer systems and other industrial products.

We proactively address design difficulties and delivery challenges. We do not wait for our customer to find an issue. dlhBOWLES is committed to quality- and our record speaks for itself. During the production process, we believe how a vendor responds to a customer’s need is just as important as meeting the deadline and staying on budget. dlhBOWLES Fluidics is a proven supplier to global leaders in automotive and non-automotive industries who trust us to sweat the details, so they don’t have this burden.